Introduction

This laboratory is mainly capable of actually carrying out preliminary processing, cutting, grinding, polishing and other pre-processing of various types of test specimens for the production of metallographic test specimens. To enable students to understand the principles and operation methods of various metallographic equipment, and to actually conduct various metallographic specimen production, microstructure observation, and testing of mechanical properties such as hardness.

| Item | Instrument | Function description | Picture |

| 1 | Automatic grinding and polishing machine (PROTH, Taiwan) |

The embedded test piece is clamped through air pressure adjustment to perform automatic grinding and polishing. |  |

| 2 | Abrasive cutting machine (PlusOver, ACA-250A, Taiwan) |

The cutting machine mainly uses grinding wheels to cut and process materials. |  |

| 3 | Water-cooled abrasive belt machine (PlusOver, PBG-436,Taiwan) |

The belt sander is a special form of grinding tool that, under a certain pressure, brings the sanding belt into contact with the surface of the workpiece, thereby performing the entire grinding process. |  |

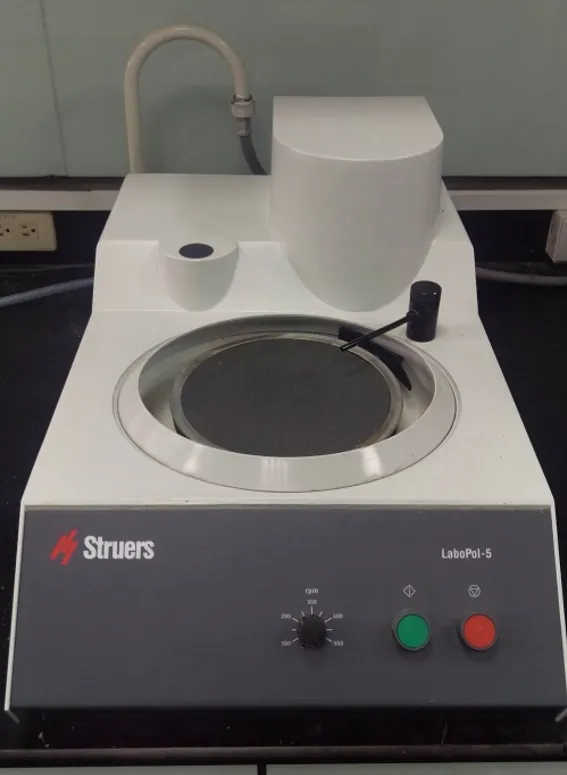

| 4 | Metallographic grinding machine (Struers, LaboPol-5. Denmark) |

The purpose of grinding is to remove the deformation layer and thermal effect layer produced when the test piece is sampled and cut. It is also to obtain a flat surface to lay the foundation for the subsequent polishing process. Grinding is divided into two categories. Those grinding with sandpaper below 120 are rough grinding. Usually the test pieces that are cut or sawed for sampling must be rough ground with 60 to 120 sandpaper first, and the remaining sandpaper numbers are 180, 240, and 320. , 400, 600, 800 to 1000 grit sandpaper for grinding. |  |

| 5 | Polishing machine (Struers,LaboPol-5, Denmark) |

After the test piece is ground, some strain layers and scratches will still remain on the surface. These strain layers and scratches must be removed by a polishing machine to obtain a flat, strain-free surface. The mirror surface of the layer. |  |

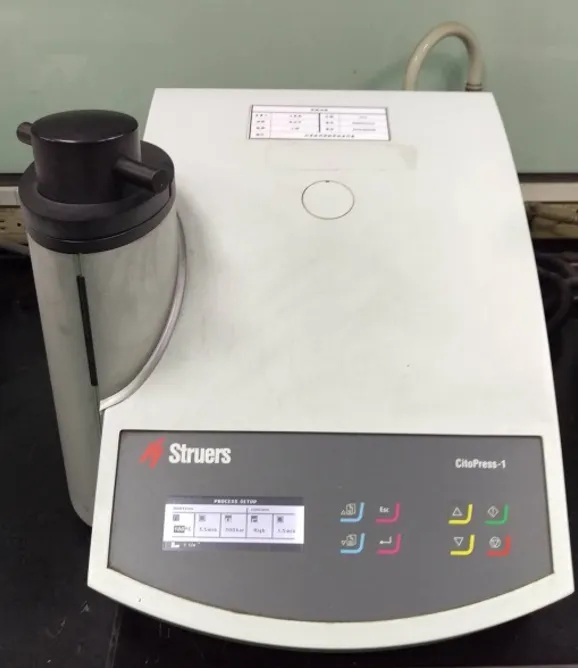

| 6 | Hot Embedding Machine (Struers, CitoPress-1, Denmark) |

The purpose of embedding is to fix test pieces with complex shapes, small sizes or difficult to hold, so that subsequent grinding and polishing work can be carried out. Hot embedding uses thermosetting or thermoplastic resin as material. The two materials must be heated and pressurized during curing. Thermosetting resins include bakelite powder and epoxy resin. They can be demoulded directly at high temperatures after hardening and usually have higher hardness. |  |

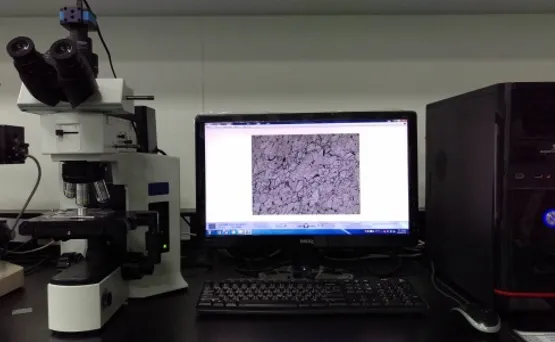

| 7 | Optical Microscope (Olympus, BX51M, Japan) |

The light source reaches the sample through the condenser, and then reaches the observer's eyes or other imaging instruments through the objective lens, reflector and lens, thereby observing the microstructure of the material. The magnification of this instrument is 50X, 100X, 200X, and 500X. |  |

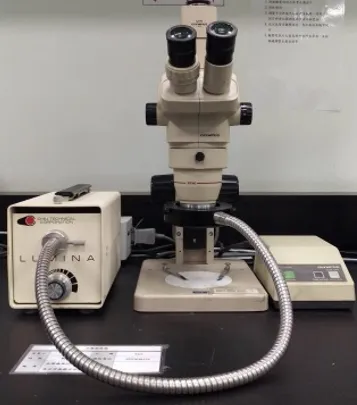

| 8 | Stereo Microscope (Olympus, SZ-PT, Japan) |

Stereomicroscope, also known as solid microscope or dissecting microscope, is a microscope designed for different working needs. A stereomicroscope can be used for observation. It is often used for surface observation of some solid samples, or for work such as anatomy, watch making, and small circuit board inspection. The sample can present a three-dimensional appearance. |  |

| 9 | Micro Vickers hardness machine (AKaShi,MVK-H11, Japan) |

Vickers-Hardness, referred to as HV, is one of the indentation hardness tests, and its measured value is expressed in HV. Compared with other hardness tests, the micro Vickers hardness test has the following advantages: the hardness value has nothing to do with the size and load value of the indenter; there is no need to change the indenter according to the softness and hardness of the material; the square indentation outline has clear edges, making it easy to measure. Used for hardness (HV) measurement of ferrous metals, non-ferrous metals, cemented carbide and surface carburizing, nitriding layers and other materials. |  |

| 10 | Rockwell Hardness Tester (KaShi, ATK-600, Japan) |

The Rockwell hardness tester test is simple to operate, fast to measure, the hardness value can be read directly on the indicator table, and the work efficiency is high, making it one of the most commonly used hardness testing methods. Used for testing various steel materials. Common hardness types include HRA, HRB and HRC. |  |