Introduction

This laboratory is mainly engaged in material mechanical and physical quality testing such as material tensile testing, abrasion testing machines, and micro-hardness. Established in response to the teaching and research needs of materials physical property measurement experiments, metal materials experiments, metal process experiments and materials topics at the university level, students can improve their understanding of the mechanical and physical properties of materials through operational training on analytical instruments.

| Item | Instrument | Function description | Picture |

| 1 | Dynamic and high temperature tensile testing machine (MTS) | This tensile testing machine can perform normal temperature and high temperature tensile tests, normal temperature compression tests, bending tests and other tests to understand the mechanical properties of materials during plastic deformation at normal temperatures and high temperatures. |  |

| 2 | Universal testing machine | Can be engaged in general tensile experiments. In addition, by selecting a suitable fixture, tensile, compression, bending and other tests can be conducted to understand the relevant mechanical properties of the material. |  |

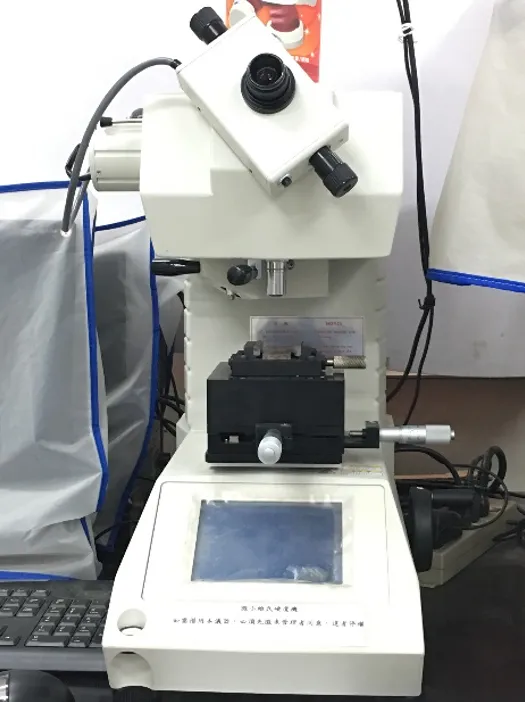

| 3 | Micro Vickers hardness machine SHIMADZU |

The surface of the sample is pressed with a very small load, and then the diagonal length of the indentation is measured using a microscope. The Vickers hardness is measured based on the conversion relationship between the diagonal and the test force. Since the load and indentation are very small, it will be suitable for hardness measurement on the surface of small-sized test pieces or thin sheets. |  |

| 4 | Abrasion testing machine Pin-on-Disk |

The machine is mainly composed of a specimen holding disc and a wear wheel shaft. Run at a set number of revolutions with different loads as a test piece for wear resistance measurement. Surface visual inspection, thickness change measurement, or weight difference measurement can be used to compare the wear resistance of test pieces. |  |

| 5 | Spot welding machine | After current passes through the welding head, resistance heat is generated in the contact surface area between the welding head and the metal test piece, which can form an instant thermal welding, so it is also called resistance welding. Resistance welding can be used to join metal test pieces and wires. Currently, it is mainly used in metal thermocouple wire joint welding. |  |

| 6 | High frequency melting furnace | Put high-melting-point metal into a coil that passes high-frequency current, causing the metal to generate a high-energy induced current due to electromagnetic induction. The metal raw materials can be rapidly heated and melted, and are used to make various advanced alloys (nickel base superalloy) preparation. |  |

| 7 | Impact testing machine | The principle of the impact testing machine is mainly to use the principle of energy conservation to calculate the impact energy according to the energy loss after the pendulum breaks the impact sample, thereby measuring the toughness of the material. |  |

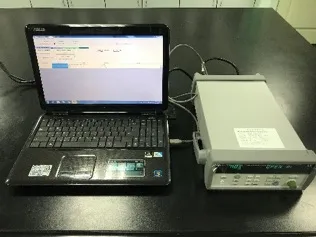

| 8 | Data logger Data logger |

This equipment mainly supports the required course of this department - material physical property measurement experiment. It can mainly support thermocouple and furnace temperature calibration and electrical data collection experiments. It can simultaneously record temperature or electrical signals at 11 different locations over time (in milliseconds), allowing students to conduct material physical property measurement experiments. |  |