Introduction

Metal material processing can be carried out through arc melting and vacuum casting technology. This laboratory was established to meet the various metal materials required for metal materials and metal process experiments in the university. Through the operation of smelting and casting equipment, one can learn the preparation techniques of various metal materials and gain a better understanding of their properties.

| Item | Instrument | Function description | Picture |

| 1 | Arc melting equipment | Use high-temperature arc to melt and mix the metal raw materials under an argon protective atmosphere, and use the suction casting method to prepare the molten metal liquid into the required thin plate or cylindrical alloy. |  |

| 2 | Optical microscope | Use optical lenses to operate under visible light to magnify the image of the metallographic structure. |  |

| 3 | Grinder (PROTH, Taiwan) |

The grinder mainly uses a grinding wheel to grind the outer cylindrical surface, flat surface and inner circular surface of the test piece to achieve the final size and flatness of the test piece. |  |

| 4 | Small sawing machine | A small horizontal metal band saw machine, which uses a saw bow equipped with a saw blade for reciprocating motion, can safely and accurately cut or saw and grind workpieces or materials. |  |

| 5 | Drilling machine (customized) |

A machine tool that uses a drill to process holes in the workpiece. It can drill through holes, blind holes, etc. on the parts. After replacing special tools, boring, enlarging, reaming and other processing can also be performed. |  |

| 6 | Precision slow speed cutting machine ISOMET Low Speed Saw |

Control the cutting speed by changing the weight load to obtain precise cutting. The diamond cutting blade used can be used to precisely cut the required specimen size. |  |

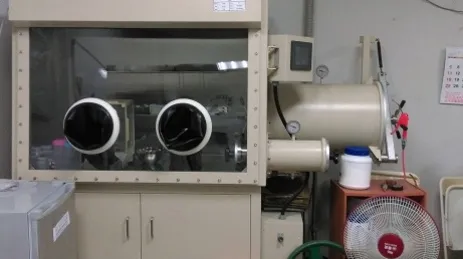

| 7 | GBS-125 glove box | A large experimental operation platform that can conduct experiments in vacuum or protective gas (such as argon, etc.) to isolate the air to avoid oxidation reactions of some metal materials or to protect the experimenter from toxic chemicals Drug harm. |  |

| 8 | Precision cutting machine ACM-250SAV | Using a double-seat screw clamp, the object to be cut (including irregular objects) can be clamped, and the cutting surface can be cut with precise horizontal feed, and the cutting surface is highly accurate. |  |

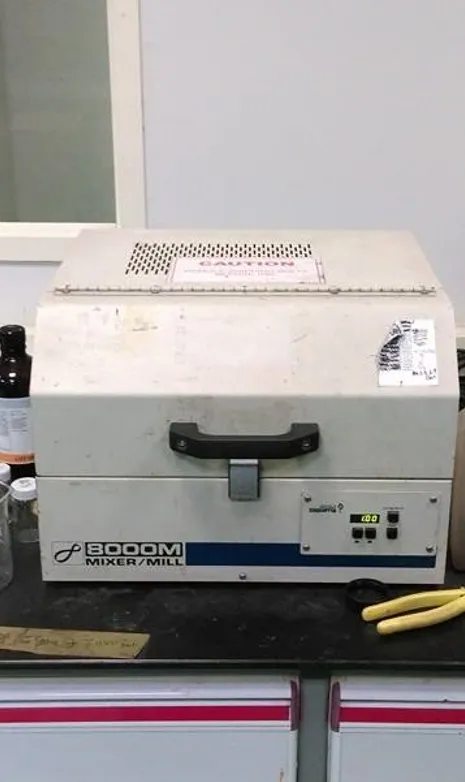

| 9 | Optical ball mill mechanical alloy machine Spex Certiprep 8000 Mixer/ Mill,8000 ball mill |

Dry ball mill has a built-in cylindrical body and a spherical grinding body. It can use the centrifugal force and friction generated when the body rotates to continuously make the inserted raw materials and grinding body interact with each other. Impact produces grinding, mixing and alloying effects. Fine and uniformly mixed element or alloy powders can be prepared. |  |

| 10 | Small rolling mill | Suitable for experimental hot and cold rolling to explore the effects of rolling ratio and subsequent recrystallization treatment on material properties |  |