Introduction

To meet the needs of university materials processing experimental course teaching, research and cooperation with industry. This laboratory equipment covers various equipment such as alloy smelting, processing/forming, welding/joining, hot-dip galvanizing simulation and heat treatment.

| Item | Instrument | Function description | Picture |

| 1 | Experimental melting furnace | This smelting furnace has high-efficiency heat exchange and relatively low radiation heat loss. The inner wall of the furnace is made of special high-temperature resistant refractory bricks. It does not contain any iron components. In addition to ensuring the stability of the chemical composition of the casting alloy , the crucible has a longer life, and this furnace is mostly used in the design and preparation of aluminum alloy materials. |  |

| 2 | 5Kg level vacuum melting furnace (VIM) | The principle of vacuum induction melting is to use the magnetic lines formed by induction to interact with the raw materials in a vacuum, causing eddy currents in the raw materials to cause a melting effect. VIM technology mainly avoids the reaction between active elements (such as aluminum, titanium, etc.) in high-temperature superalloys and air. These elements can easily form oxides, nitrides and other intermediaries with gases when smelted in the atmosphere, which will affect the mechanical properties of the alloy or Formability, etc. |  |

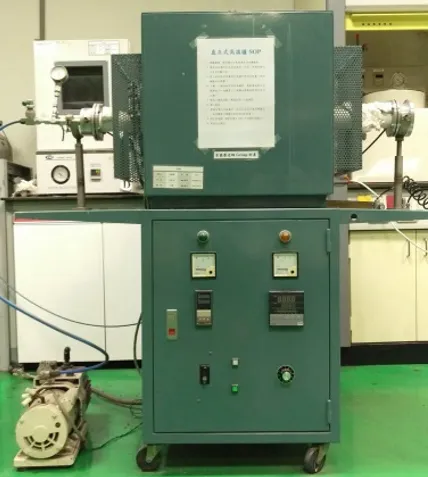

| 3 | Vertical heat treatment furnace | The purpose is to use a vacuum pump and control the flow of various gases to control the internal atmosphere of the tubular furnace for sintering, and match the temperature required for the test piece production process to perform sintering. |  |

| 4 | 1000-1700°C various box-type heat treatment furnaces (LINDEBERG BLUE) |

The heat treatment of materials produces different phase changes and unique properties with time and temperature changes. This laboratory provides experiments on preparing materials at temperatures between 1000-1500 oC. |  |

| 5 | Various high temperature and ultra-high vacuum tube furnaces | The machine is suitable for high-temperature heat treatment experiments of super alloys. It performs high-temperature annealing at temperatures above 1000 °C with a vacuum degree higher than 10-4 Torrs to avoid atmospheric contamination of materials and their properties. Influence. |  |

| 6 | Hot-dip galvanizing simulation equipment | A simulation testing machine designed based on the hot-dip galvanizing production line, used for hot-dip plating alloy design and process parameter design. |  |

| 7 | Linear automatic welding equipment | TIG, MIG and arc welding equipment, the machine is equipped with a rail car for constant speed semi-automatic welding |  |

| 8 | Vacuum tubular annealing furnace | High-temperature vacuum annealing is performed on the film test piece, and the material lattice will be rearranged to improve the crystallization and density of the film. It can be passed into a protective atmosphere or vacuum annealed, suitable for heat treatment of metal films and composite films. |  |

| 9 | Electrical high temperature box sintering furnace (Kote Enterprise Co., Ltd., kt-20/30 FB-110K, Taiwan) |

The test pieces are heat treated at different heating rates and temperatures under program temperature control. |  |