Introduction

Provide university and graduate students with the process and experiments of functional ceramic-related materials, including powder preparation, slip molding, slip casting, drying, and sintering. In addition, oxide powders are also prepared through chemical methods, such as chemical co-precipitation and hydrolysis. The laboratory also contains ceramic material processing equipment such as ball mills, uniaxial tablet presses, cold equalizers, immersion coating machines, etc.

| Item | Instrument | Function description | Picture |

| 1 | Ball mill | The ball mill method is the most commonly used crushing and mixing device. When the ball mill tank rotates, the grinding balls in the grinding tank impact and grind the materials to achieve the purpose of crushing. Generally speaking, the higher the mill speed, the higher the crushing efficiency, but when the mill speed exceeds the critical speed, it loses the crushing effect. |  |

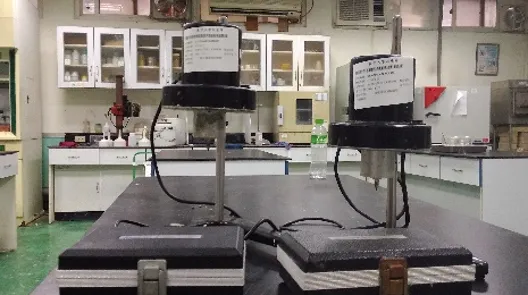

| 2 | Screening machine | To select powders in a specific particle size range, sieve analysis can generally be used. The shaking screen machine uses horizontal left and right swing oscillation, can use several screens at the same time, has a fixed speed, and can replace human operation. It is an economical screening method. |  |

| 3 | Low temperature incubator | It can form a low temperature and constant temperature (-20~20°C) environment to carry out reactions or synthesis. Component aging experiments can also be performed. |  |

| 4 | Brookfield viscometer | The casting characteristics of the slip casting method are affected by the degree of powder dispersion in the slurry. Solid castings obtained from a well-dispersed slurry have high density and mechanical strength. In contrast, if a solid casting is formed from a poorly dispersed slurry, it will have high porosity and low mechanical strength. Use a viscometer to measure the relationship between the viscosity of the slurry and the dispersant to prepare a slurry with good properties. |  |

| 5 | Double-door high-temperature furnace | The heating element is MoSi2, the operating temperature is room temperature to 1700℃, it can have multi-stage automatic temperature control, S type thermocouple, SCR control. Double-door lifting type, using the characteristics of this lifting function, the test piece can be quickly cooled and the performance of the furnace can be protected from damage. Mainly used in the production of ceramic materials and glass melting experiments. This high-temperature furnace can be used to conduct research on related ceramic materials, including the calcination of various ceramic powders and the sintering of blocks. |  |

| 6 | Hydraulic tableting machine (tablet press) | Dry press forming is a process in which powder is cast into a hardened metal mold with a punch to make a ceramic body. Dry press forming is usually used to manufacture parts with simple shapes. The thickness needs to be greater than 0.5mm, and the surface in contact with the punch needs to be a flat surface. The finished products manufactured include magnetic and dielectric ceramics, spark plugs, cutting tools, sensors, floor tiles, household porcelain, refractory bricks, grinding wheels, etc. |  |

| 7 | Vacuum oven | Use a vacuum pump to evacuate the cavity to form a low vacuum, which lowers the boiling point of the solvent and speeds up the drying speed. It can achieve a higher drying rate at a lower temperature and reduce the risk of contamination. occur. |  |

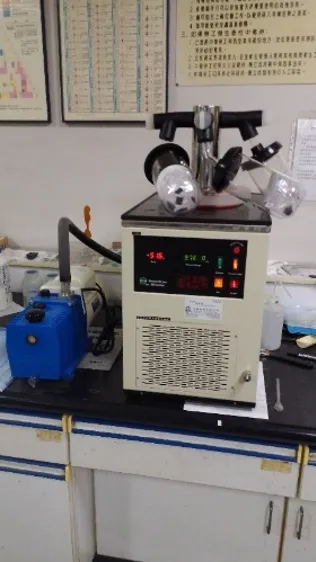

| 8 | Vacuum freeze dryer | The vacuum freeze-drying method combines three technologies: freezing, vacuum and drying. It mainly uses freezing and vacuum technology to remove moisture from the sample to reduce the humidity of the product. It can be It will not go bad if stored for a long time at room temperature. In recent years, it has been used in the preparation of porous carbon materials. |  |

| 9 | Immersion coater (Dip coater) |

The pull-up coating method (also called sol immersion method, dip-coating) is to first immerse a substrate in a plating solution containing metal ions, and then pull the substrate up at a fixed pull-up speed. After leaving the plating solution and baking the plating solution on the surface of the substrate until it dries, a film layer can be formed on the surface of the substrate. |  |

| 10 | Planetary Ball Mill | The planetary ball mill uses four ball mill jars of the same material, placed on the same rotating disk, so that the ball mill jars "revolve". Each ball mill tank "rotates" around its own axis. When the revolution speed is large enough, the centrifugal force greatly exceeds the gravity, and the rotation angular speed also increases accordingly. The grinding balls will not stick to the tank wall and remain motionless, overcoming the limit of the critical speed of ordinary ball mills. , improves the grinding efficiency, the grinding time is generally 1.5~3h, and is generally used in laboratories. |  |

| 11 | Cold equalizing press (Autoclave Engineers, America) |

Cold Isostatic Pressing mainly covers the required raw materials with a plastic rubber mold, then places them into a cavity filled with medium liquid, and uses high-pressure liquid to compress the powder into shape. After molding, the green embryo still needs to undergo a sintering process (including various atmospheres such as oxygen/argon/nitrogen/nitrogen-hydrogen mixture), which is commonly used in the development of ceramic targets in various industries. |  |