Introduction

The purpose of the establishment is to support university courses such as metal processing experiments, materials special experiments and other research and work related to functional materials.

| Item | Instrument | Function description | Picture |

| 1 | V-shaped ball mill | Raw material powders with large density differences can achieve ideal mixing effects after going through the mixing processes of rotation, cross-bonding and separation of the V-type ball mill. |  |

| 2 | Drum type ball mill (Kuanhong Instrument Co., Ltd., mubm-240-RTD, Taiwan) |

Control the speed to make the ball mill tank on the roller rotate at a constant speed, so that the grinding balls in the tank roll and mix the powder due to inertial motion. |  |

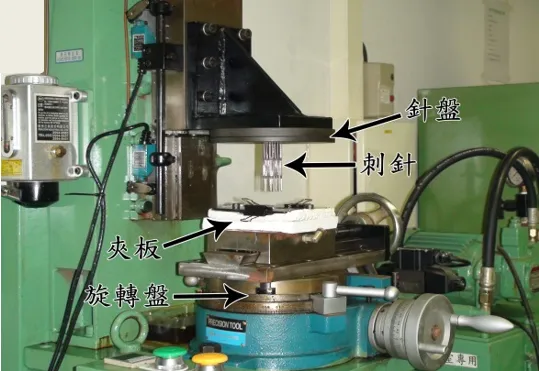

| 3 | Needle rolling mill (Self-assembly type) |

The three-dimensional needle rolling method uses external force to drive the needle hooks to entangle the fibers with each other, so that the fibers can be entangled with each other to create a fiber structure. |  |

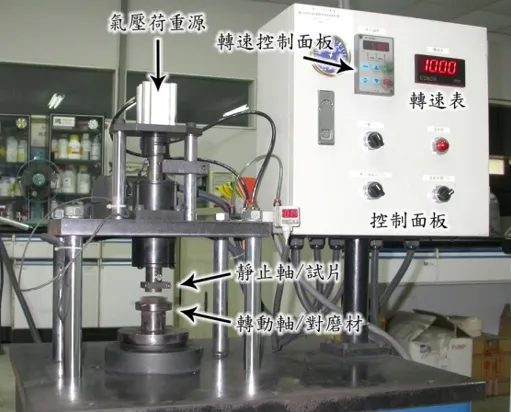

| 4 | Abrasion machine (self-assembled) |

The abrasion testing machine conducts tests in a disk-on-disk manner to measure the friction coefficient and wear amount of the test piece. |  |

| 5 | Hydraulic press | A machine made using Pascal's law and driven by liquid pressure. The hydraulic press is a type of machine that uses liquid as a working medium and is used to transfer energy to achieve forging forming, press fitting, pressing blocks and platens. |  |

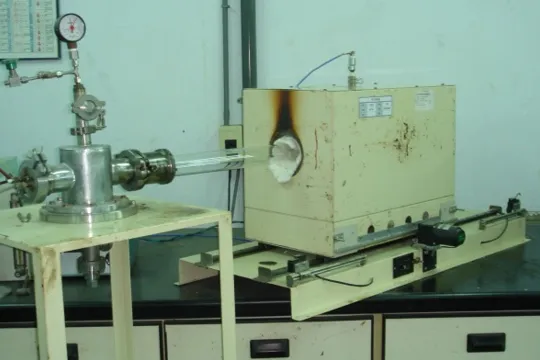

| 6 | Rapid carbonization furnace | In addition to controlling the atmosphere, this rapid carbonization furnace can also control the heating and cooling rate of the furnace body through a servo motor to accelerate the carbonization (heating and cooling) rate, thereby shortening the carbonization time and reducing process costs. effect. |  |

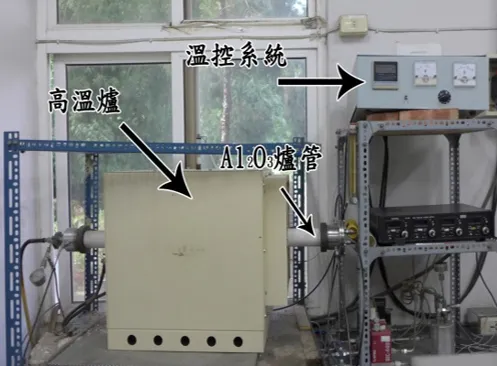

| 7 | Desktop carbonization furnace | The purpose is to remove non-carbon elements inside the material, using a vacuum pump and controlling the flow of various gases to control the internal atmosphere of the tubular furnace, and set the program according to the temperature required for the test piece manufacturing process. |  |