Introduction

Through the setting and operation of high-temperature heat treatment equipment and corrosion equipment, the high-temperature oxidation and corrosion resistance characteristics of the test piece can be analyzed. The establishment of this laboratory can be adapted to the undergraduate metal processing experiments and materials special topics courses, so that students can become proficient in the operation of high-temperature and corrosion instruments, and have an in-depth understanding of the properties of materials after high-temperature heat treatment and corrosion.

| Item | Instrument | Function description | Picture |

| 1 | Salt spray testing machine | Use salt water to produce electrochemical corrosion effects to test the corrosion resistance of various material surfaces. The basic content of the salt spray test is to spray 5% sodium chloride aqueous solution in the test chamber at 35 degrees Celsius, and compare it with the accelerated corrosion method in the seawater environment. The length of the resistance time determines the quality of the corrosion resistance. Compared with the natural environment, the salt concentration of chloride in the salt spray environment can be several or dozens of times that of the general natural environment, which greatly increases the corrosion rate. Conduct a salt spray test on the product and obtain the results. The time is also greatly shortened. |  |

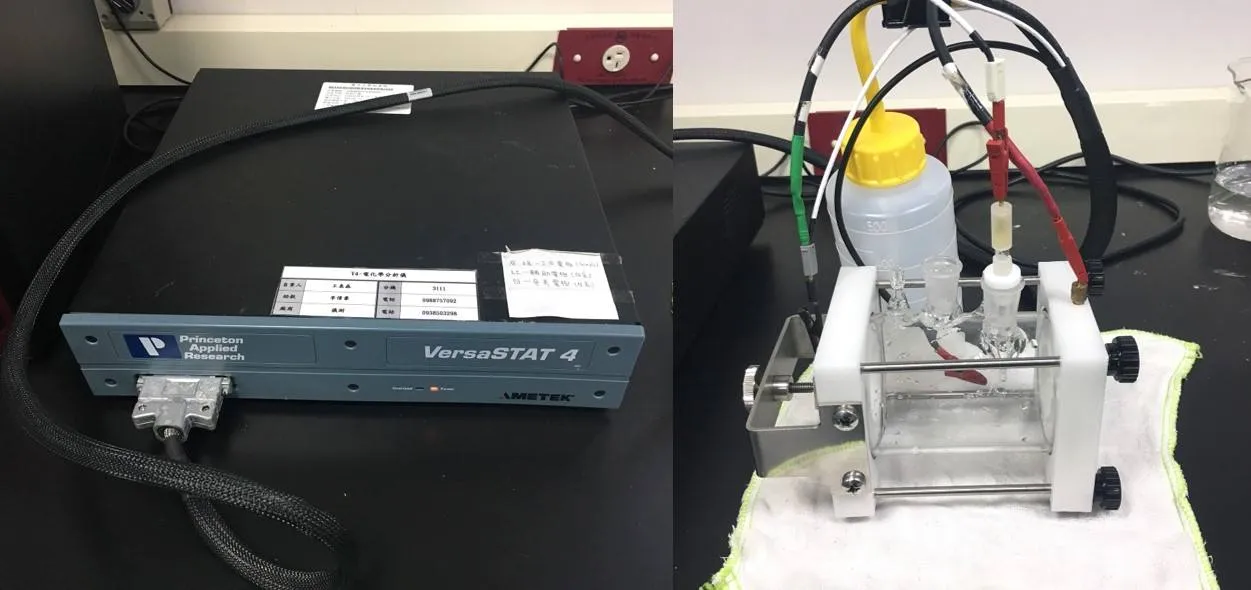

| 2 | Potentiostat PAR VERSASTAT4-400 |

Measure the potential change of metal materials in a specific corrosive environment to evaluate the corrosion current density and corrosion rate of the material. Use a potentiostat to test the potentiodynamic polarization curve. |  |

| 3 | Thermostatic bath | Observe the changes or effects on the chemical properties of the material when it is exposed to a water environment and heated to a specific temperature range to evaluate the applicability of the material in this environment. |  |

| 4 | Four-digit balance | Some precision experiments are very sensitive to weight requirements. The weight measured by the four-digit balance is accurate to four decimal places, which helps to improve the accuracy of experimental measurements. |  |

| 5 | DC power supply | Material surfaces usually require different etching methods to clearly observe microscopic features. Among them, DC power supply can use electrolytic etching to electrochemically treat the surface of metal materials to make specific features appear for easy observation. |  |

| 6 | Oven | Moisture will interfere with the accuracy of the experiment during the experiment. Powder materials require higher temperatures to remove moisture. The oven can provide environments with different temperatures to volatilize excess impurities or moisture in the powder. |  |

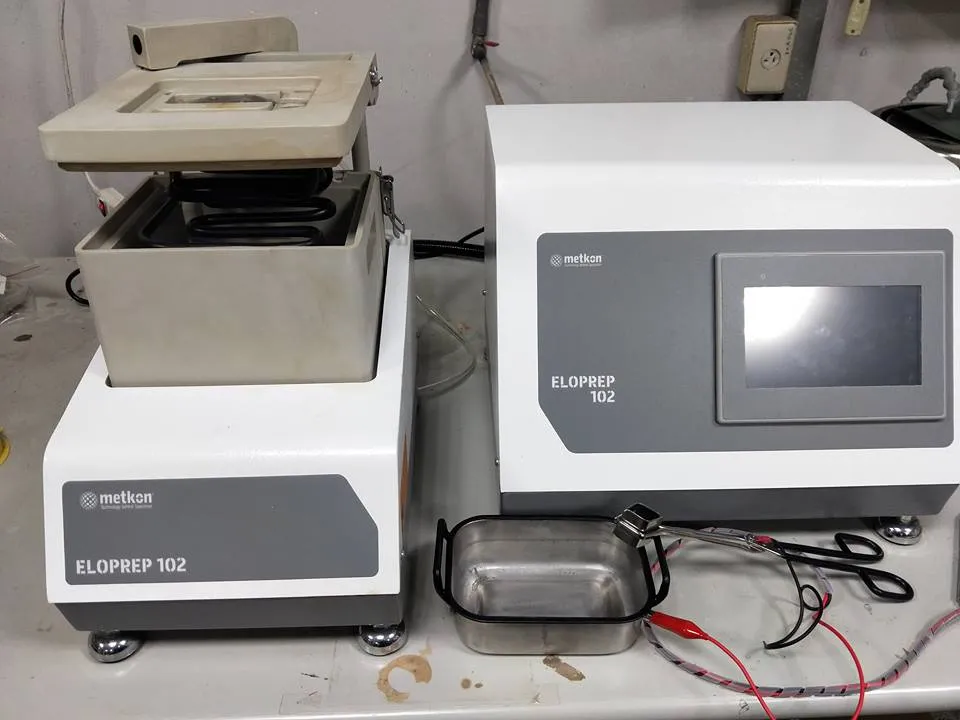

| 7 | Electropolishing | Anodic electrolytic machining technology that places the workpiece in a special electrolyte and applies appropriate voltage and current to cause an anodic electrolytic reaction to occur on the surface of the workpiece to achieve flattening, glossing and passivation. |  |